|

The

typical Cableway Conveyor system is much like an “erector set” in which few

components can be utilized to form almost any configuration imaginable. By using

idle corners, vertical curves, and quick dips, a Cableway system can be

customized to compliment operation. Small radius turns allow the Cableway system

to be utilized in tight production areas that might otherwise be inaccessible to

floor conveyors or other types of material handling equipment.

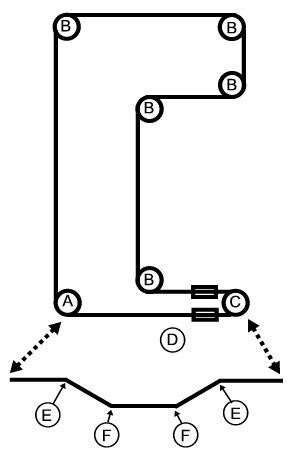

The

sample below depicts a typical Cableway Conveyor system:

The Typical Cableway

Conveyor system consists of track, trolleys, cable, drive corners, idler

corners, dip sections, vertical curves, track adjusters, and trolley fittings.

Following

is a brief description of each of the major components:

- Track:

Trolleys ride on an inverted tee rail complete with hanger brackets for

suspension and end brackets for splicing rail into a continuous rail system.

- Cable: The

standard cable used on AOC Cableway Conveyors is a pre-stretched 1/4"

or 3/8" diameter, 7 X 19 stranded core, galvanized, aircraft quality

cable. The standard galvinized cable is equipped with pressed on (swagged)

galvanized driving lugs on 12" centers.

Cable elongation is minimized by the use of pre-stretched aircraft cable

with a safety factor of 8 to 1 (based ultimate strength).

- Trolleys:

Cableway trolleys are fabricated for strength, interchangeability, and

economy. Trolley side plates made of heavy gauge pressed steel, zinc plated

for maximum corrosion resistance. Trolley wheels are supplied for loads

ranging from 80 to 125 lbs. (per trolley) and with lubrication fittings and

bearings selected to meet varying operating conditions.

-

Cable:

The standard cable used on AOC Cableway Conveyors is a pre-stretched ¼”

or 3/8” diameter, 7 x 19 strand core, galvanized, aircraft quality cable.

The standard galvanized cable is equipped with pressed on (swaged)

galvanized driving lugs on 12” centers.

Cable elongation is minimized by use of pre-stretched aircraft cable with a

safety factor of 8 to 1 (based ultimate strength).

- (A) Drive:

The AOC standard drive unit is a complete component and is furnished as

either a 90º or 180º corner with

sprocket diameters of 15-1/4”, 22-15/16”, or 30-9/16”.

The endless cable is pulled through the rail by a cast iron drive sprocket

riding on a rugged anti-friction roller bearing. Sprockets have slots that

mesh with trolley/cable lugs, which propel the trolley/cable through the

rail system.

- (B

and C) Idler

Corner: Idler corners

are used on all horizontal curves. Idler corners align and guide the cable

and trolleys through horizontal curves. The corners are constructed of heavy

gauge steel members incorporating a section of inverted curve tee track.

Cast iron sprockets with rugged anti-friction bearings are mounted to the

idler corner frame. Idler corners are available in diameters of 15-1/4”,

22-15/16”, and 30-9/16” for ¼” diameter cable. 22-15/16” diameter

sprockets only are available for 3/8” cable.

- (E, F and G) Vertical Curves:

Loads can be transported from one elevation to another by using vertical

curves. This feature allows loads to be transported from floor level to

overhead, from first floor to second or third floor, and from one building

to another. Vertical curves also can be used to dip loads in vats for

chemical treating, painting, etc.

A typical elevation requires a minimum of two vertical curves. Top and

bottom vertical curves are constructed of standard tee track bent to the

required radius and arc. The top and bottom curves are normally fabricated

in two sections, on systems with minimal inclines. Systems requiring long

inclines will consist of two vertical curves and a straight track section.

The use of two-piece or three-piece curves is predicated only by the

physical size of the incline.

- Quick Dip (not

pictured):

Quick Dip corners are similar to bottom vertical corners except for the fact

that they allow a load to be quickly lowered and raised. The quick dip is

primarily utilized when a load must be lowered into a tank and immediately

removed. Quick dips are constructed of a rigid steel frame complete with tee

track and rotating idle sprockets. The section is very similar to a

horizontal idle curve except that it mounts vertically in lieu of

horizontally.

-

Track

Adjusters: Track adjusters are used

to adjust track length in order to make up slack in the cable system. The

adjusters are typically mounted at a 180º

turn on the “slack side” of a system.

-

Inline Take Up (D):

Track

adjusters are used to adjust the track length in order to make up slack in

the cable system. The adjusters are typically mounted at a 180º turn on the

"slack side" of the system

Cableway

Conveyor Menu

Anatomy

Cableway

Conveyor Calculation and Design - 4 Steps

Technical

Data

Sample

Cableway Line Pull Calculation

Questions

that need to be answered for your Cableway System

Drive

Selection

Track and

Fittings

Trolleys

Trolley

Attachments

Load

Clearance Chart - VERTICAL CURVES

Load

Clearance Chart - HORIZONTAL CURVES

Drive

Units

Idler

Corners

Vertical

Curves

Vertical

Dip

General

Data

|

![]()

![]()

![]()

![]()

![]()